Get operational answers instantly with QSEE.

Gone are the days of getting lost in endless piles of data. QSEE tells you what requires your attention now and helps you take action.

How It Works

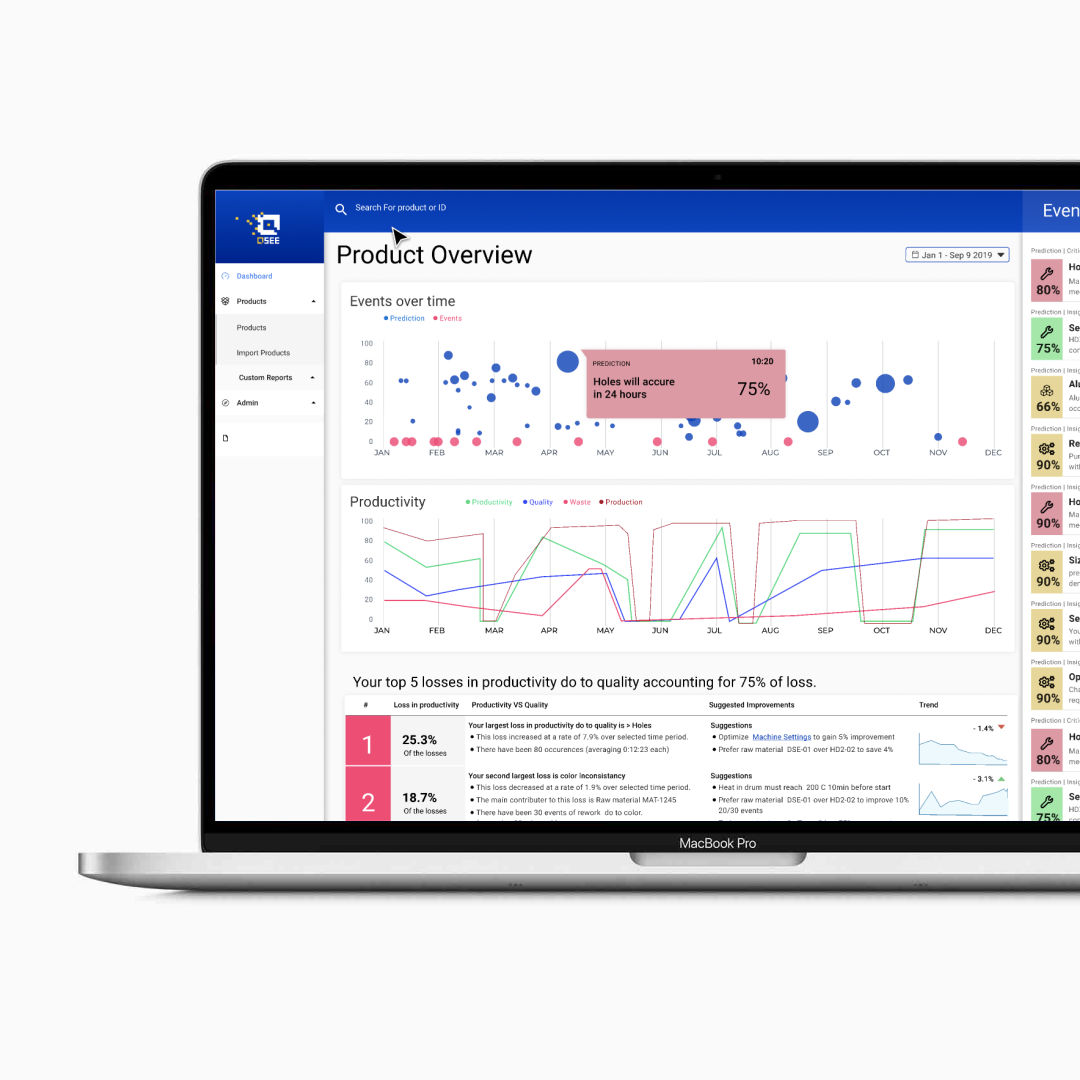

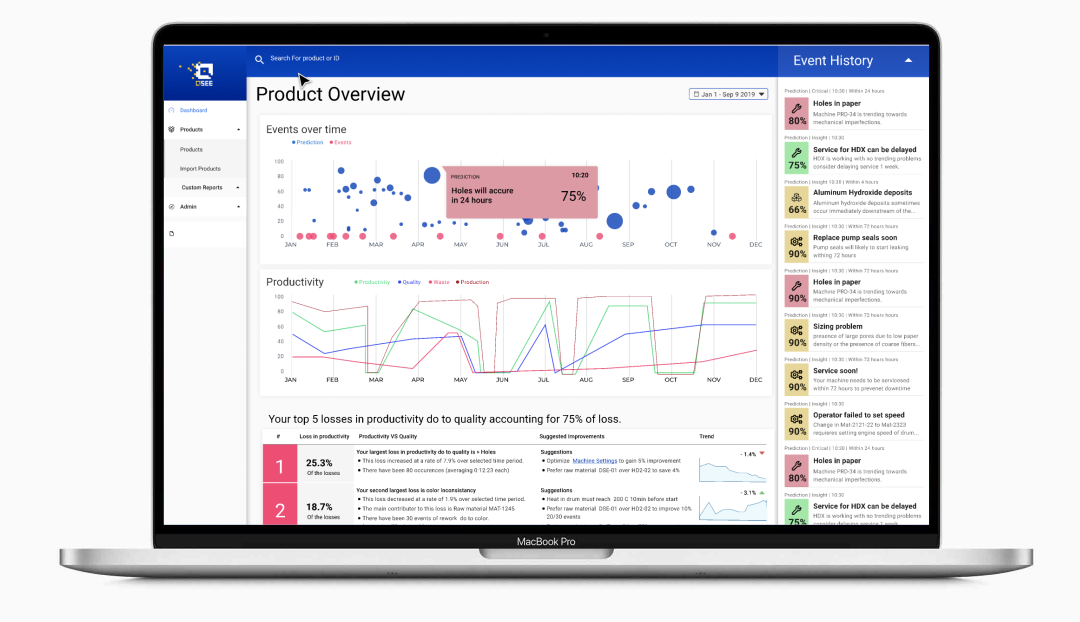

QSEE’s software only solution and predictive analytics helps you transform your manufacturing process, and product quality, thanks to our AI and machine learning technology.

Get real-time quality predictions, root-cause analysis, prescriptions and alerts to prevent downtime and improve your production results.

- Get actionable insights to drive results

- Understand production trends and stay ahead of the curve

- Only receive the information you really need.

Real-Time AI Powered Process and Quality Predictive Analytics for commodity manufacturers

Insights

Predict the future

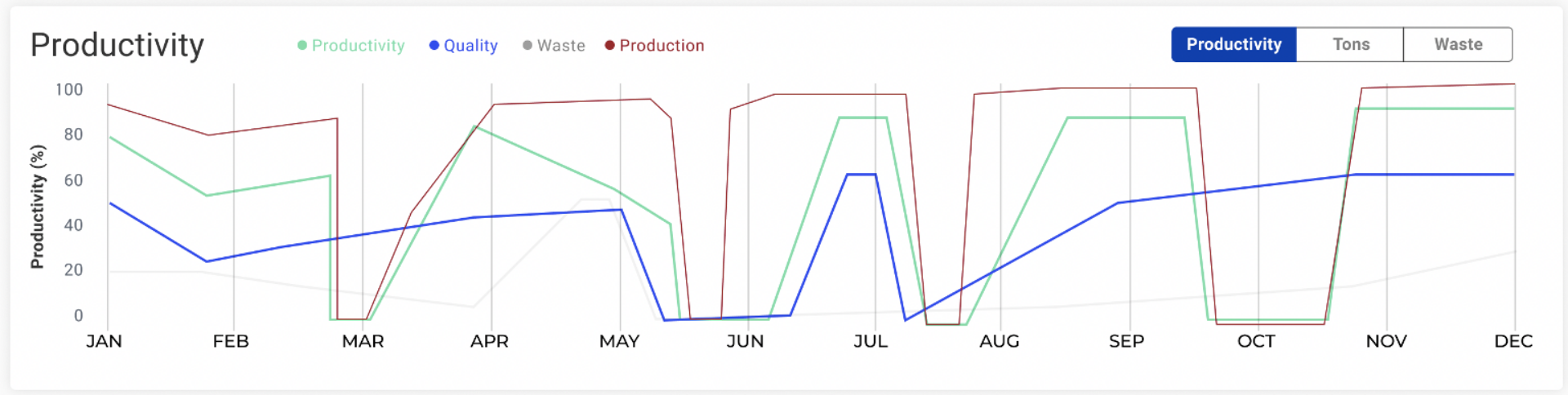

Get your KPI value instantly with real time quality trend insights for a greater manufacturing process and fewer defects.

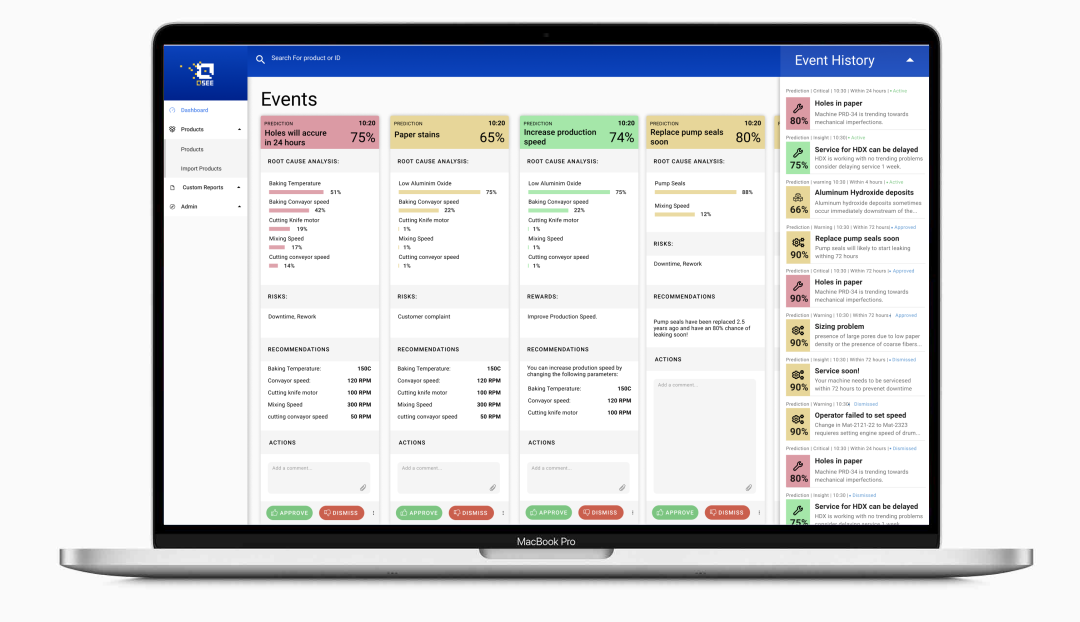

Supervised Auto-Steering™

Receive actionable operational insights so you can automate your processes, improving both quality and yield.

Easy Event Tracking

Set your parameters, track, and compare multiple KPIs thanks to our actionable insights sent to you in real time. Use these to identify anomalies and take preventive measures ahead of time.

Automated reporting

Free up operation teams by saving hours on reporting with scheduled reports at the click of a button with no code and no fuss. Automatically find rout cause contributors and reveal hidden trends and insights.

Key Features

Predict and Prevent in Real Time

By using real time root-cause analysis and visualisation, you can –

Discover unknown patterns and relationships that impact production quality

Use the power of deep learning to analyse millions of data combinations to identify trends as well as key operation and quality drivers

Identify the root-causes and contributors to failure in real time and receive insights to improve product quality by optimising your production lines

Reduce Downtime and Costs

Optimal production process maintenance –

Apply machine learning to cross-analyse data sources and predict process failures and quality issues before they happen.

Save hours of time performing manual data analysis, enabling your operation team to be-proactive rather than reactive.

Insights and alerts before-time, not just-in-time and never too late.

Empower Your Operation Team To Take Action

By automating proper responses to problems, team leaders can –

Evaluate and prioritise actions in real time.

Track production operation and provide insights regarding the best course of action.

Define rules that flag and prioritize problems.

We provide a FREE demonstration to see how our software could have helped your productivity and products quality issues over the past year.

See instantly just how much you could save into the future through our quick and easy trial.