QSEE saves 15000 TPD gold mine’s over $850,000 annually

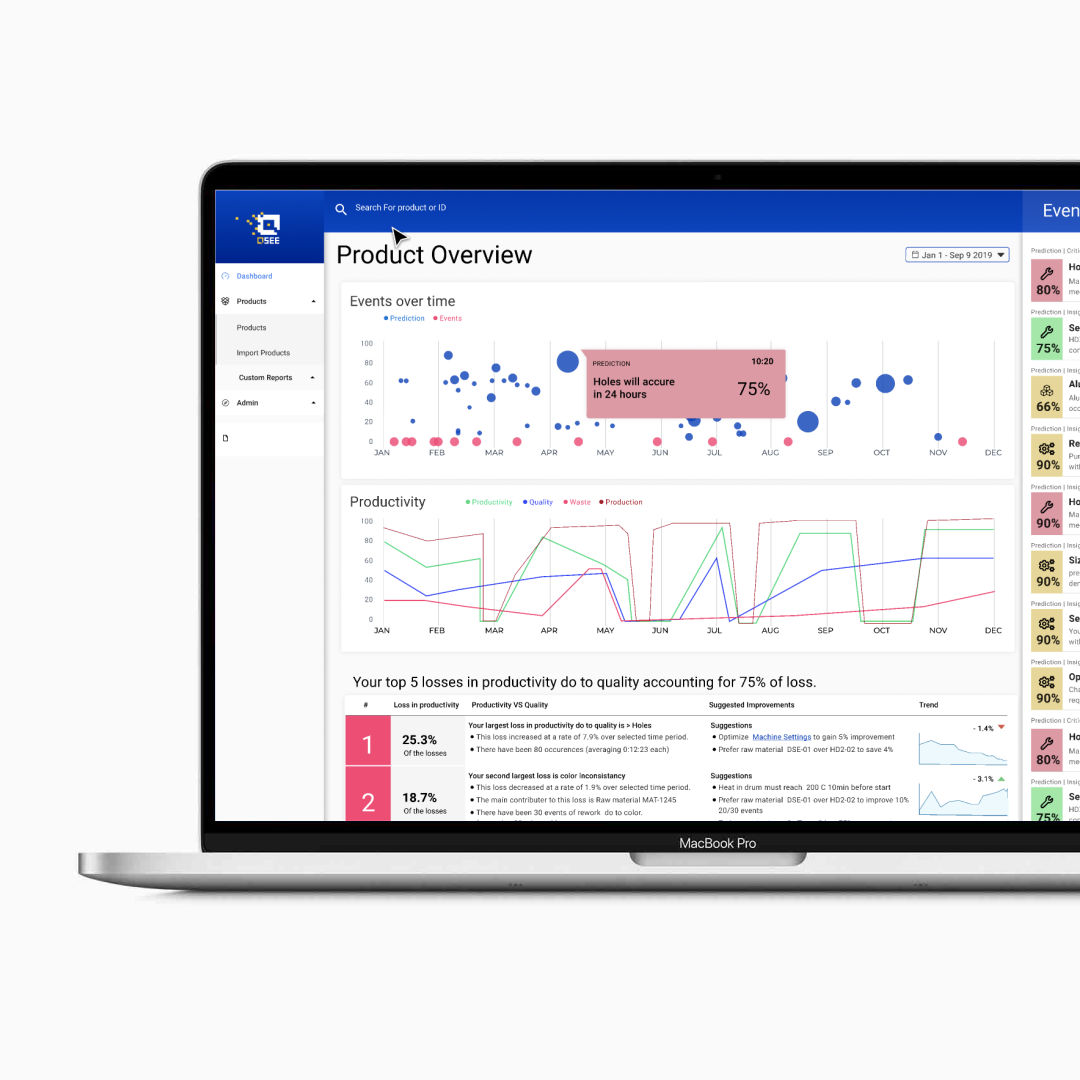

Our Zer0-Defect ® provides mine operators with real-time insights and detailed recommendations on how to minimise deviation, saving time and money.

Mining

How it works

QSEE’s process and product quality control technology, harnesses AI technology to guide operators with predictions and prescriptive actions to improve product yield, production uptime and upgraded quality outcomes.

Step-by-step Process

5. Close the loop and automate your processes with Autosteering™

Save time, money and emissions with QSEE

Find out how we can make your business greener and more cost-efficient with our non intrusive, software only technology.

We provide a FREE demonstration to see how our software could have helped your productivity and products quality issues over the past year.

See instantly just how much you could save into the future through our quick and easy trial.