QSEE optimises your cement quality and production process by more than 15%

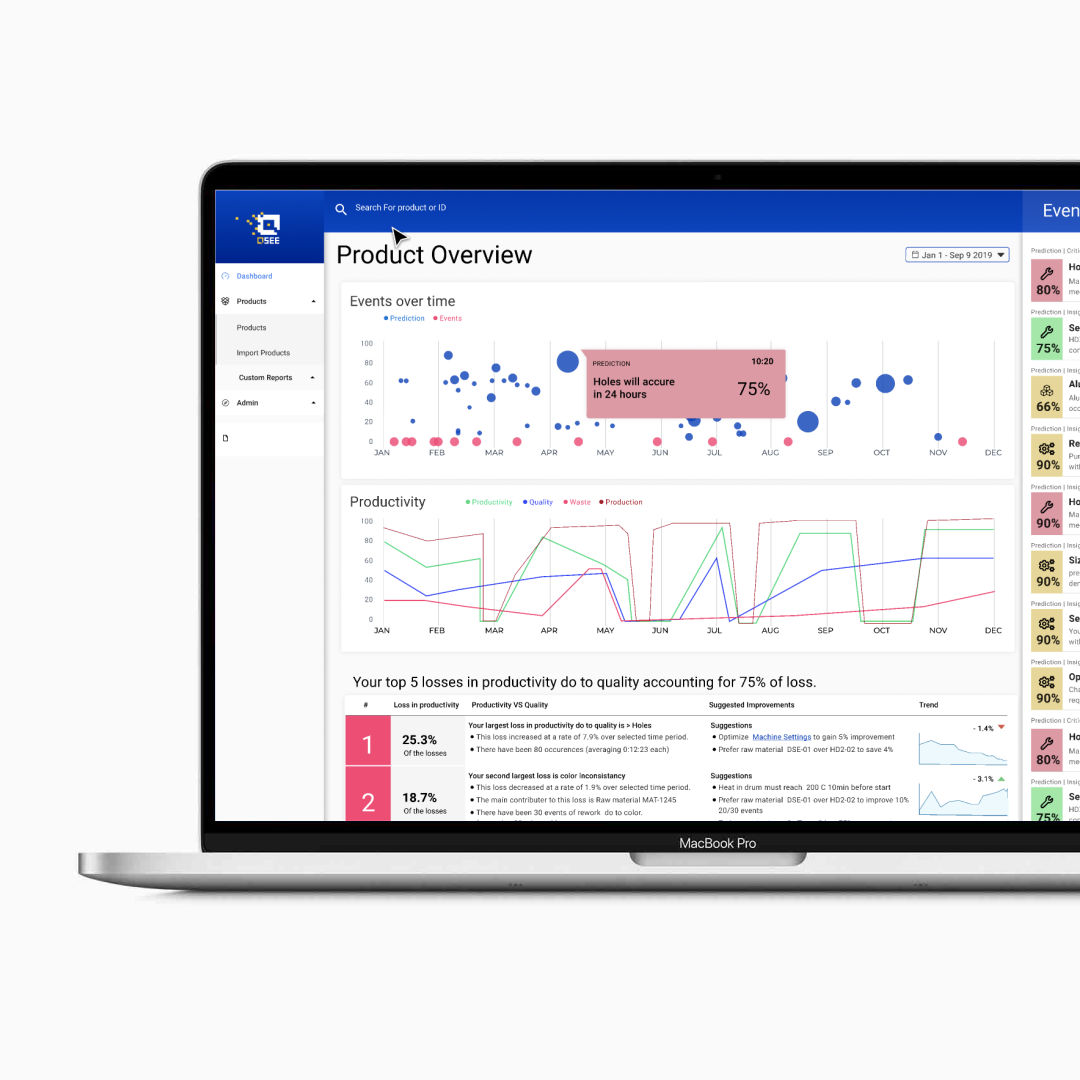

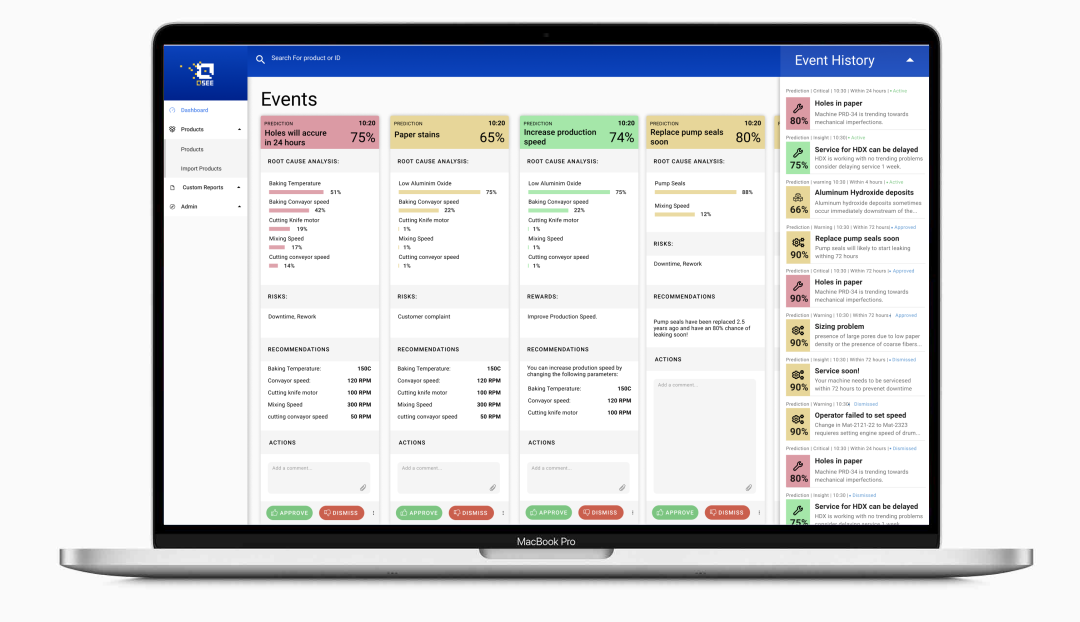

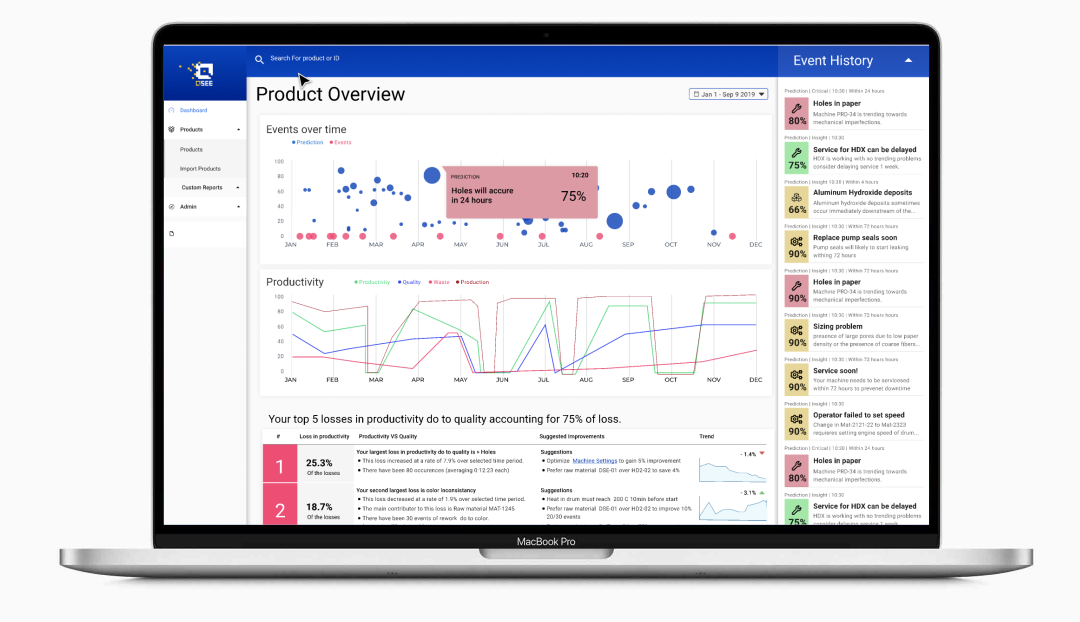

Use software-only predictive analytics to transform your process and product quality, with real-time quality prediction detection, root-cause analysis and intelligent insights to improve the quality of production results.

Building Materials

How it works:

QSEE delivers real time predictive insights for better processes and less strength defects.

Thanks to QSEE’s AI and machine learning technology, smart manufacturers are saving time, money and producing better products time and time again.

QSEEs unique AI can independently, intelligently, and automatically understand the multitude of value combinations, trends, and dependencies between thousands of production variables, production line machine, sensor readings, and other sources to produce quality results and suggest the optimum ways to approach the production of high-quality outputs, ensuring energy, materials, and human resources are better used in the context of the supply chain.

Reduce process deviation, get less faults, less wastage and improved energy consumption saving you both time and money.

Cost Savings in concrete production due to a decrease in defects could be approx. $1 Million per plant for businesses having 100+ sites across the globe.

Features & Capabilities

Early prediction of strength failures

Early prediction of quality issues

Continuous failure prediction

Production Product quality analysis

Improve Kiln quality

Improves process stability

Save quality lab cost

Ensures quality control

Step-by-step Process

Help your operations team to take action, today

By automating proper responses to problems, team leaders can evaluate and prioritise actions in real time.

We provide a FREE demonstration to see how our software could have helped your productivity and products quality issues over the past year.

See instantly just how much you could save into the future through our quick and easy trial.